U-MAP Launches Full-Scale Product Development Support Using “Thermalnite®”

– From Small-Scale Trials to Joint Development and Mass Production: One-Stop Thermal Management Solutions –

U-MAP Co.,Ltd. (Headquarters: Chikusa-ku, Nagoya, Japan; CEO: Kenji Nishitani), a deep-tech startup originating from Nagoya University, is pleased to announce the official launch of its comprehensive development support services centered around Thermalnite®, its proprietary fibrous aluminum nitride (AlN) single-crystal filler.

U-MAP Co.,Ltd. (Headquarters: Chikusa-ku, Nagoya, Japan; CEO: Kenji Nishitani), a deep-tech startup originating from Nagoya University, is pleased to announce the official launch of its comprehensive development support services centered around Thermalnite®, its proprietary fibrous aluminum nitride (AlN) single-crystal filler.

By leveraging the unique characteristics of this fibrous filler, U-MAP enables both high thermal conductivity and mechanical strength—difficult to achieve with conventional spherical fillers—even with minimal loading. The company now offers support across all stages, from initial feasibility testing to full-scale co-development and mass production.

🔹 Thermal Management Challenges and the Thermalnite® Solution

As electric vehicles (EVs), power devices, and 5G/6G communication modules continue to evolve toward higher power densities, there is a growing demand for advanced thermal interface materials (TIMs), thermal greases, and insulating sheets with exceptionally high thermal conductivity.

Traditionally, achieving high thermal conductivity has required high filler loading, which introduced several issues:

・Reduced mechanical strength: High filler volume makes materials brittle

・Worsened thermal performance: Increased interfacial resistance reduces dissipation

・Manufacturing constraints: High viscosity and poor moldability limit design flexibility

Thermalnite® addresses these challenges through its fibrous morphology, delivering effective performance even with lower filler volume:

・Forms continuous thermal pathways for efficient heat dissipation

・Enhances through-plane thermal conductivity (e.g., from 10 W/m·K to 14 W/m·K)

・Achieves both strength and flexibility (+290% tensile strength)

・Reduces interfacial resistance, ensuring long-term thermal stability

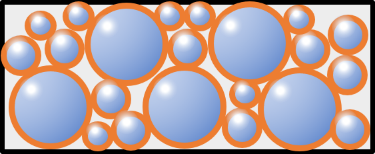

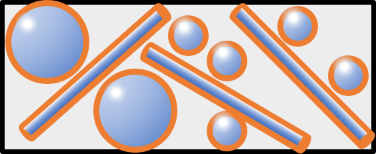

| Comparison Item | Conventional Filler (Spherical) | Thermalnite® (Fibrous AlN) |

| Filler Loading | High | Low |

| Thermal Conductivity | 〇 | ◎ |

| Mechanical Strength/Flexibility | △ | 〇 |

| Structure |  |

|

| Advantages/Disadvantages | Difficult to balance conductivity and flexibility due to high filler volume | Achieves both with minimal addition of Thermalnite® |

🔹 Case Study: Silicone-Based TIM

In collaborative projects with actual clients, the following improvements have been observed:

・Thermal conductivity: +40% (10 → 14 W/m·K)

・Tensile strength: Approx. 3x increase (0.11 → 0.43 MPa)

・Workability: Reduced viscosity due to lower filler content

These benefits lead to greater design freedom and faster development cycles.

🔹 Support Tailored to Development Stages

U-MAP offers flexible support aligned with each customer’s development phase, beyond simply supplying Thermalnite®.

<Contract Testing>

・Evaluation of compatibility and basic properties with your resins

・Surface treatment and compounding with customer-supplied resins

*Note: Thermalnite requires specialized conditions to avoid breakage or agglomeration—optimized in-house by U-MAP

・Measurement of thermal conductivity and sample fabrication (sheet, paste)

<Joint Development>

・Customizing Thermalnite® (length/diameter control) for specific needs

・Hybridization with other fillers for advanced material design

・Comprehensive evaluation: thermal conductivity, mechanical strength, dielectric properties, etc.

🔹 Target Applications

・EVs: TIM adhesives for battery modules, thermally conductive encapsulants

・Communication Devices (5G/6G): RF-compatible TIMs, EMC shielding materials

・Power Devices: High-voltage insulating TIMs and sheets

・Optoelectronics: LED/LD sealing materials, thermally conductive adhesives

🔹 R&D Capabilities

・Deep material science expertise from joint research with Nagoya University

・Full in-house mixing, dispersion, and evaluation facilities at Nagoya R&D Center

・Track record of selection for NEDO and METI national R&D projects

🔹 Message to Industry Partners

From small-scale exploratory trials to full joint development programs, U-MAP is ready to support your innovation journey.For companies struggling with heat management or researchers seeking new material solutions, Thermalnite® offers a breakthrough alternative.

📩 We invite you to contact us and explore collaboration opportunities.

https://umap-corp.com/en/contact/

🔹 Company Overview

U-MAP Co.Ltd.

Address: TOIC 601, Nagoya University, Furo-cho, Chikusa-ku, Nagoya, Japan

Representative: Kenji Nishitani

Established: December 12, 2016

Business: R&D, manufacturing, and sales of advanced thermal interface materials

Website: https://umap-corp.com

Contact Information

Business Development Division – PR & Marketing Group

Email: pres.office@umap-corp.com